How are IIOT and Enterprise Businesses Driving Results beyond Expectations and Strategies?

What is the Industrial Internet of things (IIoT)?

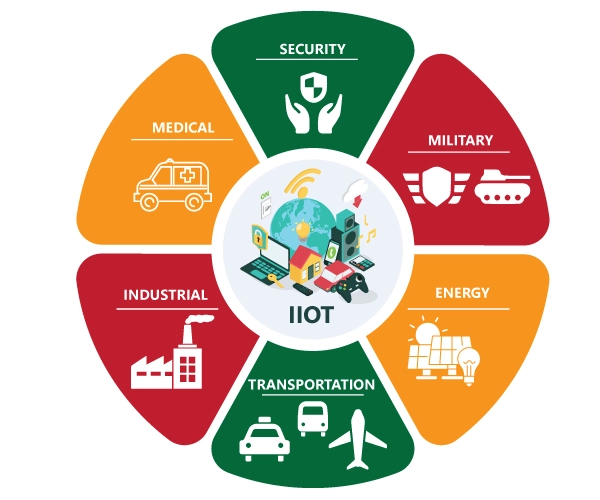

The industrial internet of things (IIoT) is the application of smart sensors and actuators to significantly improve development of industrial processes. IIoT, also known as the IIoT or Industry 4.0, takes benefit of big information that “dumb machines” have produced in industrial settings for years using the power of smart machines and authentic insights. Smart machines are often not better than people at collecting and processing real – time data, although they are better at transmitting crucial information that can be utilized to maximize the wealth of shareholders faster, according to the IIoT’s guiding principle.

IIOT and Enterprise Business

Advancements in everything can be witnessed in all spheres of our lives – from smart cities with controlled temperatures and air purifiers to connected devices in manufacturing industries and utility sectors. Devices based on IoT are all around us – an emerging technology consisting of networks of connected devices & gadgets allowing us to soundly communicate and control operations remotely.

Furthermore, with the revolution of Industry 4.0, industries on small and medium-sized enterprises (SME) are left behind. The inequality coming forward due to the revolution is exacerbating economic unjust, the lapse in socially agile opportunities, and finally dragging down the global industrial production. To overcome the Industrial revolution in SMEs; the companies need to hire expert-skill professionals, the need for infrastructure and processes revamping, update and upgrade information and operational technology within the organizations and navigate the nascent technology landscape which is currently poised to serve large-scale enterprise companies.

The IoT market-revenue is approximately $215 billion, increasing with every passing day. If we look at the last three decades, IoT has changed everything – increasing with a surprising rate in the automation industry. Not just the automation industry, the technology industry is the one who gained the most from IoT. IoT and IIoT both pushed every industry known to mankind to connect as many plant-floor devices to their enterprises’ systems for the higher-level data analytics which assists the higher-management to make timely decisions to optimize their productions and supply demands.

Attributes of IIoT and assistance for Enterprise Businesses

Integrated their already-acquired technologies with their IIoT products; the industries are delivering the complete end-to-end enterprise systems, not a mere complete prototype. The result of this has some drastically positive effects on users – IoT and IIoT both ease the problem users succumbed while processing the much-needed digital data transformation of organizations. Pilots and siloes environments are no longer the only places IIoT is. The magic of this industrial revolution with a glimpse of 5G is what the world acknowledged as the technological miracle.

With IIoT, industries can, with a speed unimaginable to common man analyze, adapt, transform, optimize, and get the desired results for their businesses. With every new day, industries transforming with the practical deployment of IIoT-integrated devices. In the blink of an eye, every industry, organization, offices, and institution are adapting the emerging technology. The rapid adaptation is elevating debates from bombastic IoT objectives to market size range challenge, from intriguing experiments on substantial IIoT implementations to its impact on lives and on future to come.

The challenge & strategy of IIoT effecting Enterprise Businesses

With, IIoT provides us with a platform that is capable of rapid processing, data analyzing, and contextualizing the organization’s data which has various data forms and transforms all as the one. Industries consist of complex data and even complex information systems and data sources sitting idly in silos. The challenge here is to stitch up and integrate those data sources as one.

The strategy to solve this issue is simple: IIoT is proficient to do the tedious task. Without IIoT, the task is tedious and time-consuming. IIoT integrates the data packets in silos transformed into digital information which then rapidly drives value for companies, including internal operations for manufacturers and productions – the results exceed the expectations of time-saving and efficiency.

IIoT spread its roots in approximately all the industries – from manufacturing to utility sectors, from production to FMGC, from healthcare to educational institutions, from offices to plat floors. But some organizations still cling to their legacy systems which are being obsolete and left them with no choice but to pressure them to adopt the assistance of IIoT. Organizations that refuse to accept the services of IIoT had succumbed to the brink of extinction, few of the fortunate once faced disruption in digitizing the new setups.

Feature of IIoT in Enterprise Business

With real-time assessing to dashboards to view and make the decisions regarding productions and planning across various factories by a manufacturing CEO to an operator merely taps into asset-level data to maintain seamless operations and uptime.

IIoT promises operational efficiencies and optimizations through analysis, connectivity, and automation. Embedded with information and communication technologies, manufacturers achieve exceptional insight and plant-floor visibility to access production phases and processes, identify gaps and lapse, fixing the errors whilst ensuring product quality.

A unique feature of IIoT is it doesn’t require organizations to take every device and equipment out and install new once. No, special-built sensors, as well as chips, will be attached to the equipment on the plant. Be it the ancient computers or latest hand-held devices enabling them to relate to the network of devices over LAN, Ethernet, or Wi-Fi.

Benefits of IIoT includes:

- A manufacturer with a mammoth of machines and devices connected with an IIoT platform can save approximately millions/year through energy conservation single-handedly.

- With the assistance of the IIoT platform, a plant supervisor can automate the lighting control in the factory, shutting down idle machinery, controlling air conditioning, resulting in saving significant amounts of dollars.

- IIoT provides machine performance indicators as well – the supervisor will know when to shut down a machine or scheduled downtime for maintenance. This feature leads to seamless operations.

- IIoT guarantees to avoid disruption in manufacturing and production processes. Unplanned shutting down of machine for maintenance resulting in not just delay in productions but also in terms of exorbitant cost.