What are Digital Twin Technologies?

A digital twin is a virtual representation of the physical object, process, entity, environment, or system. It not only looks like the real world but also behaves like it. In other words, we can say that it is a digital counterpart that presents dynamic and in-depth simulations of real-world images.

We can create digital twins by collecting data from different sources like IoT devices or sensors and replicating the process. It allows us to predict possible outcomes and problems that real-world processes or products might experience.

Digital twins have three main aspects: data modeling, acquisition, and application. We use specific technology in digital twins depending on the need, extent, and application. Four technologies are involved, including the Internet of Things (IoT), cloud, extended Reality (XR), and artificial intelligence (AI). These help collect and store real-time information, provide valuable shifts, and create a digital representation of a physical object.

In this blog, we will understand digital twins, how it works, the relationship between IoT and digital twins, and its benefits and challenges.

How Do Digital Twins Work?

For creating digital twins, we mimic physical objects by gaining a complete understanding of biological systems or things. In other words, we use in-depth data from physical objects or systems to develop a mathematical model that simulates the real world in digital space.

The constructed twin receive data from real-world counterpart from sensors. In this way, the digital twin simulates the physical system in real-time. We can also design a digital twin as a prototype of a physical object before it uses in its original version. It helps to refine products and allows businesses to create quality products.

How is Digital Twin Different from Simulation?

We often use the term digital twins and simulations interchangeably, but they are completely different with different applications. We design simulations with CAD systems or another related platform. We can place it via its simulated paces, but it may not have one-to-one analog with a real object. In contrast, we can build a digital twin with real-world sensor data. It can easily replicate a real-world system and even alters that system time-to-time.

During the design phase of the product lifecycle, we use simulations to predict and evaluate how our product will behave in the real world. On the other hand, we use digital twins to get business insights and details of the system or products we are using already.

What is the Role of IoT in Digital Twins?

IoT is the backbone of digital twins. It provides real-time data, providing access to the real world. We use this data to create or update digital twins. Some key roles of IoT in digital twins are:

1. Real-time Data Collection

IoT devices like actuators and sensors collect real-time data from the physical environment. It can collect data of different types, allowing us to update and create digital twins as needed. With the IoT, we get a steady stream of data, enabling the digital twin to reflect the present state of the physical counterpart.

2. Data Integration

IoT devices get data from different sources. We can integrate this data with other data sets like operational data, business insights, and other relevant data. This integration enhances the application and accuracy of digital twins, and we can easily target complex issues. Also, data integrations allow us to extensively understand and resolve business issues related to production, performance, risk, and behavior.

3. Predictive Analytics

We can integrate IoT-generated data with artificial intelligence, machine learning, and advanced analytics. It allows us to enhance the predictive capabilities of digital twins. With the help of AI and machine learning, digital twins can identify patterns, analyze risks and predict future outcomes. Predictive analytics with digital twins allow businesses to optimize operations, minimize risks, and plan accordingly.

4. Remote Management

With the help of IoT, digital twins can remotely control and manage physical systems. It reduces the need for an operator to present on the system continuously. Operators can monitor, adjust parameters and even simulate different scenarios without physically being present at the operation location. It reduces the overall cost of hiring many employees, reduces management burden, increases operational efficiency, and even enhances response rate.

Role of Digital Twins in Business

Digital twins allow businesses to simulate, analyze and monitor business operations, processes, and assets in real-time.

We can use digital twins in business as simple as designing a product like a smartphone or electronic gadget, being produced digitally as a prototype for better analyses before going into production. We can monitor the status of the object and make changes as needed. In this way, it helps businesses to reduce costs and errors.

Also, we can use it as complex as a digital replica of the entire business infrastructure or operations. It is often very helpful in designing smart buildings, business operations, and cities.

Companies can make data-driven decisions, optimize operations, analyze risks, and plan effectively. Digital twins connect the realm with the physical world, allowing companies to monitor and innovate their business processes. Businesses are shifting towards digital twinning to gain a competitive advantage.

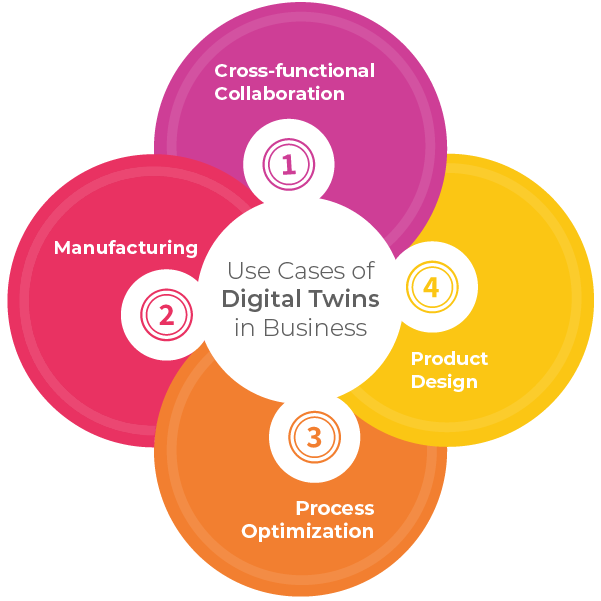

Use Cases of Digital Twins in Business

Some of the use cases of digital twins in business are:

1. Cross-functional Collaboration

With digital twins, we can collect operational data time-to-time. It provides data to improvise processes, production, distribution, and customer experience. All this becomes possible when we share data across different departments, like production, sales, and marketing. Employees across other domains can get the same data for analysis. It helps to make collaborative and improved decisions.

2. Manufacturing

In manufacturing, we can observe cases of digital twinning in different domains like simulation, remote control, and monitoring of assets with virtual objects. Also, it modifies and improves products, services, and operations according to customer demand and needs. It helps businesses achieve high customer satisfaction and business sustainability.

3. Product Design

The powerful designs of the products are one of the main reasons for the company’s success. Therefore, making the right decision with effective planning for product designs is crucial. Digital twins allow the formation of a virtual replica of a manufacturing product, which collects data and helps build, test, develop, and validate predictive analysis. Engineers use these virtual prototypes during the design phase to test different designs. It allows them to invest in the right direction for a solid prototype. It saves time, production cost, resources, and several concrete prototypes.

4. Process Optimization

Digital twins help businesses to monitor and evaluate processes under different standards and performance conditions. It helps to predict and detect issues before they occur. With digital twins, we can transform assets into tools that help to save money and optimize the process. Also, we can predict when machinery needs repair, replacement, or updates, helping to optimize the processes.

Benefits of Using Digital Twins in Business

Some of the major benefits of using digital twins in business are:

1. Training and Development

Companies, to be successful, invest in upgrading their employees. Job staff go through mental and physical stress. It reduces productivity, causes a high turnover rate, and severe health issues among employees.

Digital twins are computer-generated versions of people and can help businesses make better decisions. To monitor their level of fatigue, digital twins do wonder. We can collect patient data such as heart rate, breathing rate, temperature, and burned calories to put it in the digital twin. Through this, we can predict employee issues, like fatigue or illness, caused by doing specific tasks for a particular time.

Also, we can identify and work on their weak areas by putting employees’ data in digital twins. We can design training programs and sessions and evaluate when an employee should promote to a new position, job, or schedule.

2. Better Cognitive Abilities

We can work on employees’ cognitive abilities to take better opportunities from digital twins. We can analyze the context in which employees make decisions or make mistakes. With sensors, we can collect data for employees’ digital twins. We can design training tools to enhance their abilities by analyzing the data.

Additionally, we can capture employees’ highly skilled capabilities and learning and save their copies as digital twins. This way, their experience, and knowledge won’t be lost if they switch jobs or retire. By creating digital twins of intelligent employees, we can pass the successful approaches they adopted to other employees to teach them to fight new challenges.

3. Enhanced Safety and Risk Management

We must consider and evaluate different scenarios for risk management to make the best decisions. Digital twins are the right option for it. We can simulate asset behavior by considering unique methods. It helps businesses analyze different types of risks and hazards they can face.

This strategy allows them to enhance their practices and overcome the chances of accidents even before they occur. To further elaborate, companies develop virtual replicas of vehicles, initiating with virtual designs followed by virtual models of all the tech parts. It helps them test the cars in different risk conditions to ensure safety compliance and update the system.

4. Business Growth

Digital twins work by collecting and analyzing data in real-time. It helps to make better decisions and ultimately boost sales and profit. Businesses significantly compete in the market when they easily identify risks and take prompt actions.

To illustrate, different renowned companies have started to adopt digital twin technologies. They have altered several production sites into virtual models representing the supply chain. In this way, it enhances efficiency, reduces waste, saves resources, and meets quality standards. They can see the overall company operations by collecting data via sensors, storing data in the cloud, and generating digital twins.

Challenges of Using Digital Twins

1. High Implementation Cost

Digital twins have high implementation costs. We need software, hardware, and technicians. Also, we need to invest in training employees for it. Moreover, after implementation, if the users are not prepared, they won’t be able to take the maximum benefits from it, leading to huge losses to the business.

2. Lack of Awareness

As digital twin technology is quite new, people do not know much about it. Businesses can experience resistance and lack of interest from the side of employees. It may even result in high turnover and poor performance from employees.

3. Ethical Issues

A digital twin is an advanced technology and can easily replicate anything or a person in real-time. Therefore, there are huge ethical concerns involved. It may misuse personal information, collect data without consent, and even misinterpret someone’s reputation. Other than this, storing employees’ or patient data for personal use is also a serious ethical concern people may face.

4. Lack of Infrastructure

We need advanced digital infrastructure to develop digital twins. The development of digital twins needs a model-based environment. Companies may experience a hurdle in implementing advanced digital infrastructure for its successful implementation.

Conclusion

Digital twins have revolutionized the world by virtually representing any object, living, or system in real-time. It completely mimics the system and uses machine learning and simulations to help with reasoning and decision-making. In the business world, it allows businesses to gain a competitive advantage, minimize risks, predict different scenarios, optimize processes, and even store data of their employees in the form of digital twins. By integrating it with AI and other technologies, we can experience huge progress in productivity, data analytics, predictive maintenance, and decision-making.