Remote temperature monitoring is the most important aspect of managing cold chain logistics. Cold chain monitoring usually means using a technologically advanced or IoT-based solution to monitor the temperature-sensitive products in the supply chain continuously. The products in the cold chain include food and beverages, biologics, pharmaceuticals, etc. The inconsistency in temperature and the inability of the companies to manage the optimal temperature of the cold chain leads to a lot of food wastage.

Approximately one-third of the food is thrown annually, equal to 1.3 billion tons of food wastage, totaling a loss of $35 billion, as mentioned in the report published by UNEP. However, apart from the personal wastage of food, waste also occurs before the product reaches the market. Nearly 12% of the total food waste occurs during transportation when the temperature changes, making the perishable food go bad before it goes to the grocer.

If your fleet is transporting perishable goods such as food or beverage, then you should be aware of the risk of spoilage associated with the uncertain temperatures. The big question is, how can the fleets contribute to remotely monitoring the temperature of the cold chains? The answer is the use of a wireless IoT-based remote temperature monitoring solution for refrigerated trailer management that helps fleets monitor temperatures in transit from remote locations to prevent spoilage and rejected deliveries. Considering the cold chain problems, the following articles highlight the need for remote temperature monitoring and its benefits for cold chains.

What Is Remote Temperature Monitoring?

It is difficult to ensure consistent temperature for the perishable food in the cold chain without remotely monitoring the fleets. Environmental factors, route problems, open vehicles, humidity levels, power outages, and temperature fluctuations can contribute to spoilage and rejected deliveries. Additionally, hundreds and thousands of trailers are in transit daily, making temperature monitoring more challenging. Hence, cold chain companies use cooling techniques or smart remote temperature monitoring to prolong the product’s shelf life.

Remote temperature monitoring in cold chain logistics uses IoT-enabled sensors to track the temperature of the refrigerated trailers in which the perishable food is transported. The system ensures that the overall temperature of the cargo is maintained to keep the goods fresh and alerts the drivers or the cold chain managers if the fluctuations in the temperature occur so that the appropriate actions can be taken on time.

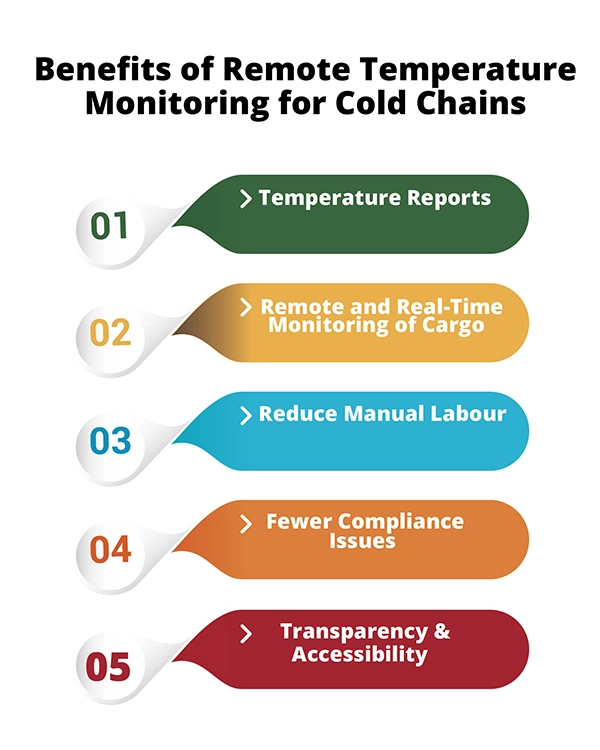

Benefits of Remote Temperature Monitoring for Cold Chains

1. Temperature Reports

The most damaging factor for the cold cargo is extreme temperatures. Too hot or too cold temperature can impact the cold chai products as per their tolerance over certain temperature levels. For example, vaccines can lose their stability when they are stored beyond temperatures between 2°C to 8°C. However, with the help of remote temperature monitoring sensors, cold chain companies can access the real-time temperature reports of the products and the vehicles when they are in transit to ensure that the temperature is not fluctuating. Such reports can be analyzed, stored, and curated by the companies anytime to pass the tests of the compliance and regulatory organizations. Smart temperature monitoring devices use GPS or WIFI to send real-time information to the cold chain companies’ drivers and managers to ensure maximum utilization of supplied products and minimize food and product wastage.

2. Remote and Real-Time Monitoring of Cargo

Accessing the temperature reports passively is helpful, but sometimes, for the time being, it becomes necessary for the managers to look at the cargo status actively as well. The managers can do this easily by using IoT-powered remote temperature monitoring systems. These devices are designed to instantly connect with GPS or WIFI and pass on all the necessary information to the managers. In case of any issue, managers can take certain actions to prevent further damage. For instance, they can reroute the cargo to a warehouse that can provide cold storage to store the perishable product temporarily, or they can alert the drivers of any temperature spike so that they can take appropriate actions. Overall, it can be said that the company’s ultimate goal is to reduce the possibility of spoilage and financial loss by using remote temperature devices to manage the cold chains.

3. Reduce Manual Labour

The most important part of the cold chain is managing and continuously monitoring the temperature. Before introducing technology in this domain, employees and drivers were burdened with constant temperature logging. Due to all this manual work, there were high chances of errors. With the help of remote temperature sensing technology, companies can cut the possibility of miscalculations or other human errors. Remote temperature monitoring devices can read the refrigerated trailer temperature as per the set instructions. Such autonomous systems do not require any human intervention and can work for a more extended period.

The most important benefit of remote temperature monitoring is to automate the temperature checking procedures in cold chain logistics and minimize the human labor and the possibility of errors to a greater extent. The drivers can focus on more critical tasks when manual labor is reduced. However, people can be employed for fact-checking and ensuring the accuracy and integrity of the information when required. This can act as the added layer for improving the quality of the information passed from the temperature sensing devices to the management, which can make data-driven decisions as per the provided information.

4. Fewer Compliance Issues

Regulatory powers such as FDA or USDA impose certain standards on the companies to ensure food safety. Failure to comply with the standards can lead to penalties and hefty fines. In case of severe violations, the risk of shutting the whole business down becomes high.

Temperature monitoring systems help the cold chain management companies align their procedures with the agencies’ regulatory requirements. These devices allow you to monitor the temperature of your product from manufacturing and storage to the shipping stages. The best part is that these temperature sensing devices can provide detailed and error-free reports about the surrounding conditions of the product, such as humidity level and temperature. This gives management a comprehensive insight into the condition of the product and the optimal temperature it should be kept in. With IoT-enabled remote temperature sensing systems, the companies can ensure full compliance no matter where their products are in the supply chain. They get alerts regarding any section of the freezer malfunctioning in temperatures or door abeyance.

5. Transparency and Accessibility

The supply chain is a complex procedure as the companies deal with both national and international deliveries, involving hundreds and thousands of trucks. Due to this difficult process, communication is also lacking, which causes hurdles in the procedures. A remote monitoring system provides real-time data of the fleet to everyone involved in the process, eliminating the concerns over the communication.

No matter the physical location or time zone, managers, employees, or truck drivers can log in to their mobile or desktop application and track the product’s exact conditions. This kind of accessibility and transparency ensures that the issues related to the temperature malfunction in the cold chain are resolved immediately before they can cause any irreversible financial loss.

To Sum up…

In conclusion, it can be said that remote temperature monitoring systems have remained quite famous within cold chain logistics from the very start, as it is a temperature-sensitive industry. The benefits discussed above indicate the undeniable potential and importance of remote temperature monitoring in cold chain logistics. The global supply chain ecosystem should utilize the saving potential of remote monitoring systems as the world is battling food waste.