Technology is revolutionizing all sectors, and to a greater extent, organizations are reaping hefty benefits from it, especially in terms of reduced labor, human errors, and automation. To keep up, traditional warehousing systems are transitioning into smart warehousing by integrating new technologies. This not only helps in improving production but also facilitates warehouse managers in increasing revenues.

Compared to traditional warehousing, smart warehousing systems are more effective, as they provide greater visibility to the companies while enabling them to make immediate changes to the system to enhance production and operation speed. Along with reducing human errors to a greater extent, smart warehousing is also suitable for ensuring standardized safety and security in the organization.

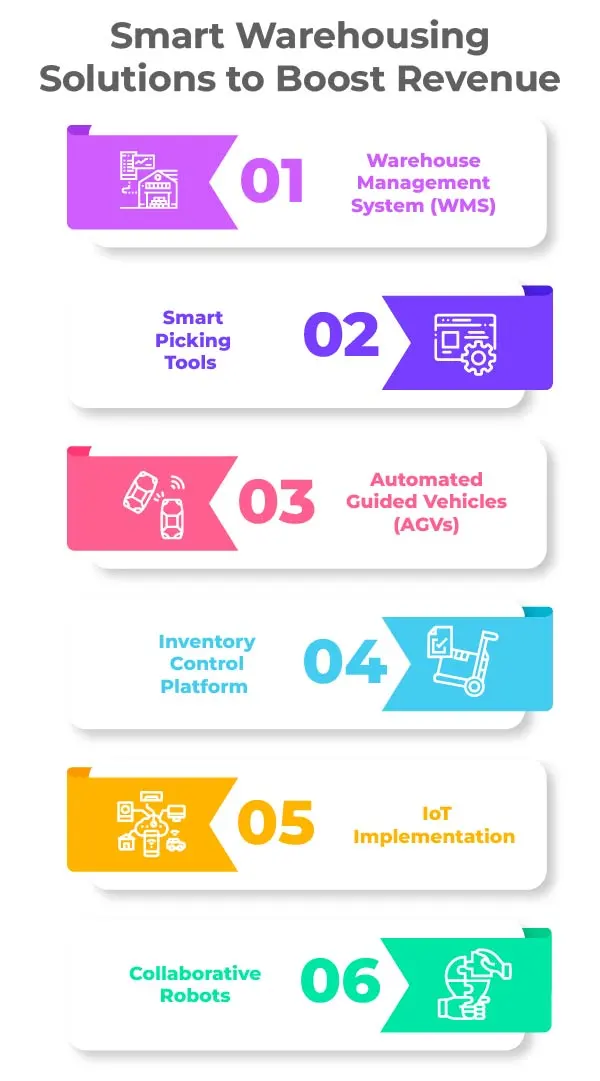

Numerous technologies can be used to develop a smart warehouse to keep operations streamlined, reduce time, and enhance revenue. The following article highlights the top 6 technologies that can be used in the smart warehouse. Still, before that, we need to understand why automation is required to manage a warehouse.

Why Automating a Warehouse is Necessary?

Consumer demands are increasing rapidly, so the optimal system that can fulfill those demands on time is needed. The ultimate solution to this critical challenge is to automate the warehousing procedures. This reduces overheads, and human error lowers the risk of injury and offers great optimization.

With the help of automation in managing warehousing activities, managers can avoid manual work and move towards digitization to reduce the cost of goods and services and create barriers of entry for competitors.

Smart Warehousing Solutions to Boost Revenue

1. Warehouse Management System (WMS)

The integration of an efficient WMS in the warehouse has the potential to accumulate all the critical data over a single platform. Through this smart warehousing solution, the members associated with your supply chain can have a complete view of the operations and real-time statistics to make data-driven decisions. The system has a role or right-based access to ensure that the warehouse data is accessible to the required personnel and prevents unauthorized data use.

WMS enhances visibility throughout the supply chain, streamlines processes, reduces cost and error, and improves stakeholder relationships. These benefits, in turn, help in increasing revenue streams. Despite being beneficial for smart warehousing, WMS needs to be chosen wisely, as the functioning of such a system must align with other autonomous procedures.

2. Smart Picking Tools

In large distribution centers, picking an element or product is performed with the help of different material handling tools. For instance, goods-to-man, automated storage, and retrieval system (ASRS), and put-to-light.

By utilizing the automated picking elements in your smart warehouse, you can benefit from the perfect picking rates, reduced manual work, and increased revenues. You can choose from various smart picking tools to complete your day-to-day operations, depending upon the products or services you are working with. Such automated tools reduce the probability of error and inappropriate handling of products and improve labor allocation by making the process easier and faster.

3. Automated Guided Vehicles (AGVs)

AGVs are fully autonomous and efficient machines that can help ramp up a smart warehouse’s retrieval and storage process. This includes stock-take, put-away, and loading of the goods. AGVs are completely autonomous and include pallet carts and forklifts. These high-intelligent, self-guided machines can follow the digital paths throughout the warehouse and perform duties like loading and unloading the boxes and containers. These vehicles are highly compatible and can easily be installed in any warehouse without changing the system and layout. The installation of AGVs showcases the smart warehouse’s ability to adopt new technologies and complements the business’s growth with unimaginable automation.

4. Inventory Control Platform

Managing inventory manually is extremely tedious and imposes the risk of errors and miscalculations. This can put the warehouse at the edge of irrecoverable financial losses. However, our jobs have become exponentially easier due to automation which is now more prevalent than ever. Complete automation is also becoming a part of smart warehousing, where managers integrate automated inventory control systems to eliminate manual work and enhance accuracy.

Automated inventory control systems can perform multiple inventory-related tasks simultaneously. These include inventory tracking, item fulfillment, maintaining order points, and monitoring real-time data. Though WMS in place is enough for inventory control in distribution centers, the use of an automated inventory control system in parallel to WMS is an added advantage. It minimizes human error, saves time, promotes scalability, and optimizes operational efficiency, resulting in increased revenues.

5. IoT Implementation

Most industries rely on the Internet of Things (IoT) to run their operations smoothly. IoT involves a sensor network that continuously shares useful information between the devices. As far as the use of IoT in the smart warehouse is concerned, it can be observed that the robots for managing the goods can easily communicate with the WMS to manage the warehouse autonomously. For instance, IoT starts working when the warehouse receives the product. On the shipment’s arrival, RFID scans the tag and sends the product information to the WMS. Later, the WMS sends the information to the robots and guides them about the place in a warehouse where that product should be kept. This happens seamlessly and automatically without harming data privacy or leaking crucial information. Moreover, IoT sensors in the warehouse can also monitor environmental conditions like temperature and moisture to keep the perishable items fresh and reduce wastage.

6. Collaborative Robots

Collaborative robots, also known as Cobots, are becoming increasingly popular in industrial settings where error-free work and immediate outputs are required. They are also becoming useful for managing modern warehouses. According to recent research, by 2029, the market size of collaborative robots will reach $8.65 billion. This indicates that using Cobots in the warehouse and other industries is less likely to become obsolete, and the technology has a promising future.

Cobots can work autonomously or alongside human beings to perform complex tasks associated with warehousing operations. This includes picking goods, loading stocks, and installing shelves while allowing human workers to remain in their work area. Cobots can perform various tasks simultaneously, work 24/7 accurately, and minimize repetitive logistics tasks. This reduces the overall operational cost of the smart warehouse and increases revenue.

Conclusion

Bringing optimization to any warehouse is the goal of smart warehousing solutions. Automation in warehouses is on the rise and will continue to prosper as more and more warehousing companies are embracing to unlock new revenue streams and not fall behind in the competition. Smart warehousing solutions take your operations to the next level by minimizing labor, reducing operational costs and errors, and streamlining warehousing operations.